Machining of engine blocks on the example of the Junak M07/M10 gearbox

I offer the service of gearbox alignment of the Junak M10 M07 motorcycle on a numerically controlled machine.

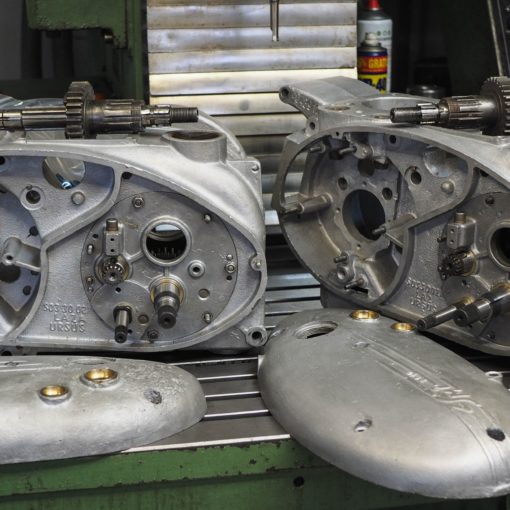

Standard service includes:

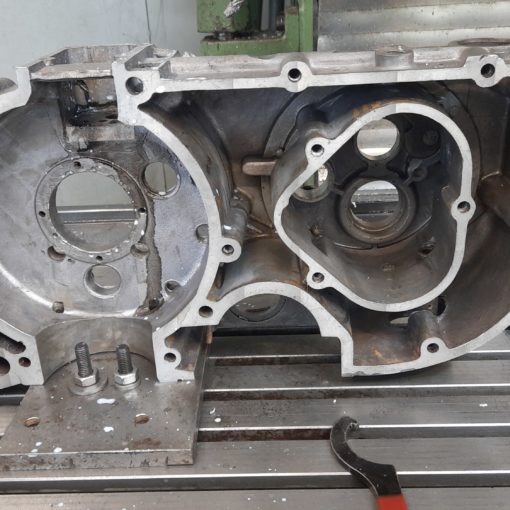

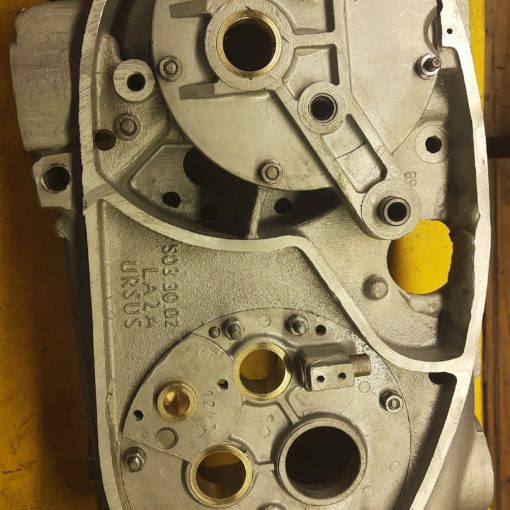

– planning the contact surface with the left cover,

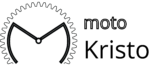

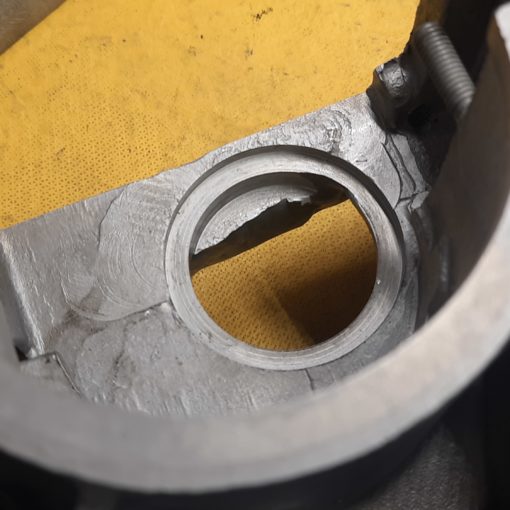

– giving the factory spacing of holes for the sleeves in the crankcase,

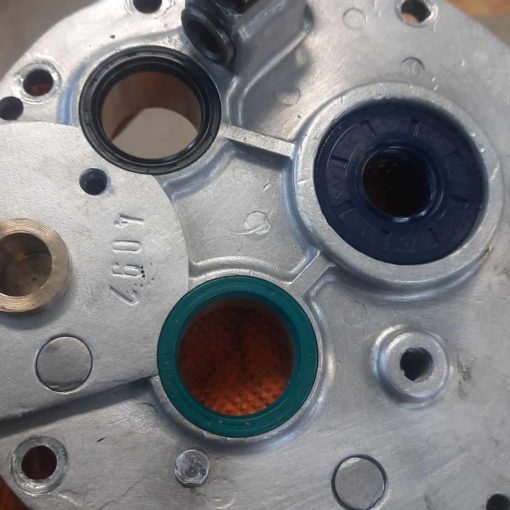

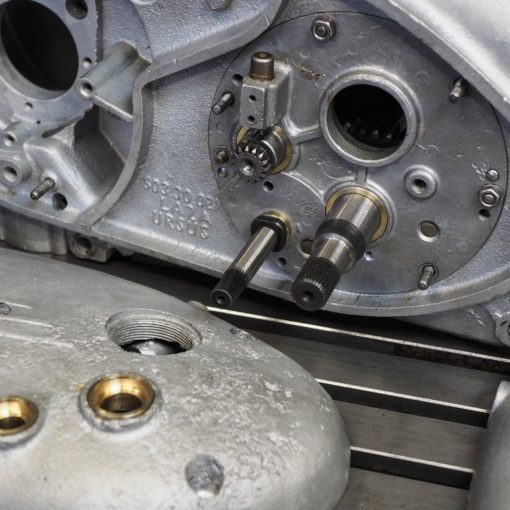

– grinding of the pins of the rollers working in the sleeves,

– making an additional hole for the pin in the gearbox cover and pinning the cover before machining,

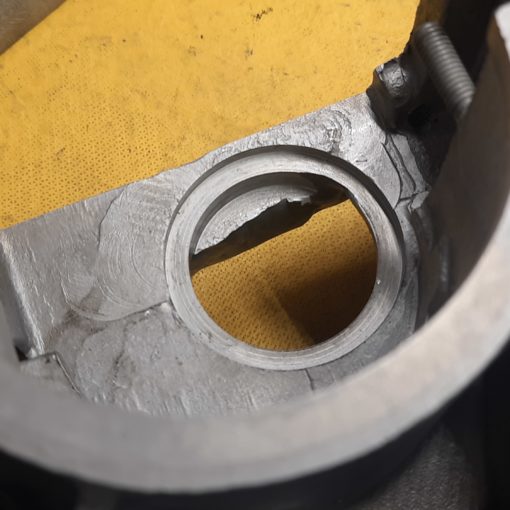

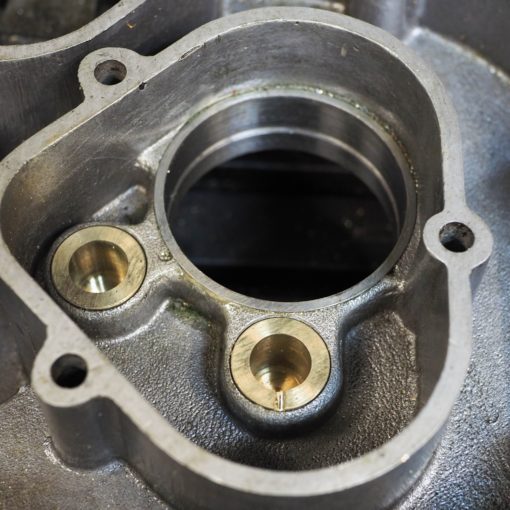

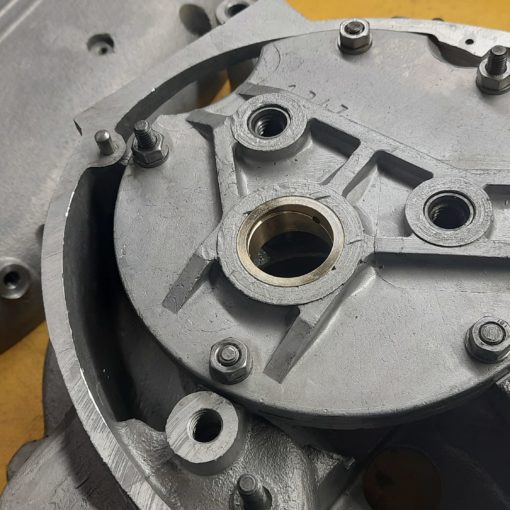

– making new bronze bushings and turning them to the dimensions of the shafts with appropriate clearance after pressing. These are the crankcase bushings (2), the gearbox cover (3) and the left cover (2),

– replacing the bushings in the output shaft (2) and boring them to size.

It is required to deliver the crankcases (from one set), the gearbox cover and the left cover clean of dirt, as well as the gearbox shafts and new shafts: starter and gear shift.

The price for the standard service described above is PLN 2,600. The cost of material is included.

The standard seal is made in the left cover (simmerrings on the starter and changer shafts). There is no seal in the box cover, the changer is in the oil. This way we avoid oil leaking into the changer chamber during standstill, which means that the oil level in the gearbox is too low.

After alignment, the gearbox rotates easily and at the same time with sufficiently small play of the shafts in the sleeves. The distances between the shaft axes are as they should be at the factory, which improves the cooperation of the gears.

After making arrangements, I can perform other processing. I do not regenerate crankshafts or machining cylinders.